Aerospace

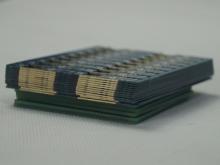

The aerospace industry requires printed circuits with high reliability in extreme conditions. Any electronic product used for flight or combat must be robust, reliable and compact. Aerospace-related electronic equipment typically requires a 50-year lifespan and needs to be able to operate well for decades.

Thermal expansion coefficient - very close to silicon, much lower than most common metals.

Excellent electrical isolation - long life even at long temperatures.

Good thermal conductivity as an insulator - good for heat diffusion.

Stable dielectric properties and low loss at high frequencies.

High chemical stability relative to many chemicals, moisture, solvents and consumables.

The aging of the material is very slow due to the consistency.

Compatibility with precious metal paste sintering technology - resulting in highly reliable conductors.

High processing temperature - away from normal operating range.

Thermal resistance: There is no typical melting, decomposition or softening.

Mechanical Stiffness - Sensors that allow rigid carriers, hardness and wear resistance to work in vacuum, fluid and industrial contaminated environments.

Anti-EUV, plasma and ionizing radiation, and virtually no deflation in high vacuum, is ideal for sensors used in EUV semiconductor devices.

Our commitment to excellence and innovation allow us to provide our customers with some of the highest quality standards and most advanced circuit board technologies found in the industry today. Our vastly expanded PCB capabilities, along with an extensive materials selection and cutting edge equipment, make us a premier PCB manufacturing and assembly company that the aerospace and defense industry can depend on.

Comments

Post a Comment