LED

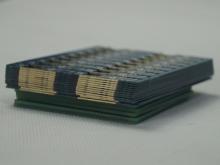

As led pcb supplier , we offer all kinds of LED PCB Product. For High-Power LED of the Aluminum Base PCB, copper base PCB, ceramic base PCB, for low-power LED of the FR4 PCB, High-Temperature PCB. As the Aluminum Base PCB of good thermal performance, High-Power LED products most commonly used Aluminum Base PCB. As one of the most professional led pcb board suppliers in China, We can give different Solder mask options for your Led PCB ,We do lots of R&D on Led PCB solder mask Lumens to give your Led lights better brightness . The Applications of LED Printed Circuit Board The Led benefits make LED printed circuit boards very desirable for a number of applications and industries. Some of the more prominent applications of Aluminum LED Printed Circuit Board include:Telecom LED PCB,Automotive LED PCB,Computer Led PCB,Medical LED PCB,Led PCB Products: Led Tube , Outdoor LED advertising screen, LED Lamp, Waterproof Led , 1.5m Led and so on. Led PCB Material...