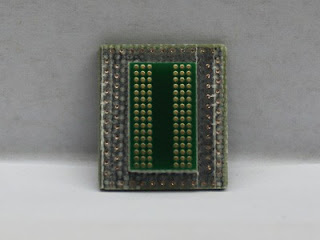

Via in Pad

What is Via In Pad The holes drilled on the chip pads on the PCB can be referred to as VIA IN PAD. In the manufacturing process, after the via plating, the resin is filled and then the surface is plated and filled, and the via is not visible when the patch is applied. As we all know, via in pad technology, the PCB plugging process is a process that is produced by the higher requirements of the PCB manufacturing process and the surface mount technology. The VIA Plugging In PCB Effect has the Following Points • Prevents short-circuiting of tin from the via through the component surface during PCB over-wave soldering • Avoid flux remaining in the vias • Prevent the soldering of the solder balls from over-wave soldering, causing a short circuit • Prevent surface solder paste from flowing into the hole to cause solder joints, affecting placement The advantage of the resin plug hole relative to the solder resist plug hole is that the flatness of the pad of the resin p