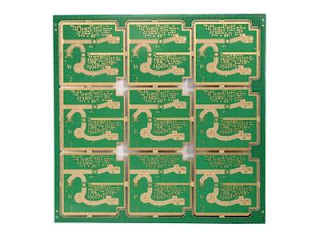

PTFE Teflon PCB

PTFE Teflon PCB has excellent comprehensive performance: high temperature resistance (-192°C-260°C), corrosion resistance (strong acid, strong alkali, aqua regia, etc.), weather resistance, high insulation, high lubrication, no adhesion, Non-toxic and other excellent characteristics.

At present, various types of PTFE pcb board have played a pivotal role in the national economy such as chemical, machinery, electronics, electrical appliances, military, aerospace, environmental protection and bridges. And we are a professional teflon pcb manufacturer.

PTFE Teflon PCB Application

The PTFE Teflon PCB is suitable for use in electrical insulation materials and linings, supporting sliders, rail seals and lubricating materials for electrical insulating materials and contact corrosive media. It is used in light industry in rich cabinet furniture. It is widely used in chemical, pharmaceutical, dye container, storage tank, reaction tower kettle, anti-corrosion lining material for large pipelines; heavy industry such as aviation and military; mechanical, construction, traffic bridge slider, guide rail; printing and dyeing, light industry, textile Industry's anti-adhesive materials, etc.

Characteristics of PTFE Teflon PCB

Low loss, low dielectric constant, good consistency, stable chemical properties, and almost no moisture absorption. It is often used on RF and microwave circuits where high requirements are required.

1) high temperature resistance - use working temperature up to 250 °C.

2) low temperature resistance - has good mechanical toughness; even if the temperature drops to -196 ° C, it can maintain 5% elongation.

3) corrosion resistance - for most chemicals and solvents, showing inertness, strong acid and alkali, water and various organic solvents.

4) Weather resistance - the best aging life in plastics.

5) High lubrication - the lowest friction coefficient in solid materials.

6) non-adhesive - is the smallest surface tension in solid materials, does not adhere to any substance, mechanical properties, its friction coefficient is very small, only 1 / 5 of polyethylene, which is an important feature of the surface of perfluorocarbon . Moreover, since the intermolecular force of the fluorine-carbon chain is extremely low, the polytetrafluoroethylene has no stickiness.

7) non-toxic - physiologically inert, long-term implantation of artificial blood vessels and organs without adverse reactions.

8) Good electrical properties - Polytetrafluoroethylene has low dielectric constant and dielectric loss over a wide frequency range, and high breakdown voltage, volume resistivity and arc resistance.

Comments

Post a Comment