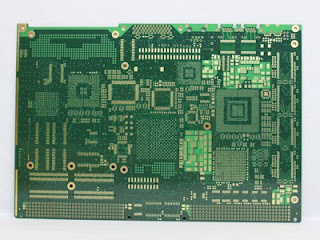

HDI PCB

HDI PCBs, one of the fastest growing technologies in PCBs, are now available at PCBSky. HDI PCBs contain blind and/or buried vias and often contain microvias of .006 or less in diameter. They have a higher circuitry density than traditional circuit boards.

There are 6 different types of HDI PCBs, through vias from surface to surface, with buried vias and through vias, two or more HDI layer with through vias, passive substrate with no electrical connection, coreless construction using layer pairs and alternate constructions of coreless constructions using layer pairs.

HDI any-layer printed circuit boards are the next technological enhancement of HDI microvia printed circuit boards: all the electrical connections between the individual layers consist of laser-drilled microvias. The main advantage of this technology is that all the layers can be freely interconnected. To produce these circuit boards, PCBSky uses laser-drilled microvias electroplated with copper.

Special Technologies Used with HDI Any-layer Printed Circuit Boards

Edge plating for shielding and ground connection

Minimum track width and spacing in mass production around 40μm

Stacked microvias (plated copper or filled with conductive paste)

Cavities, countersunk holes or depth milling

Solder resist in black, blue, green, etc.

Low-halogen material in standard and high Tg range

Low-DK Material for Mobile Devices

All recognised printed circuit board industry surfaces available

HDI PCB Technology Sheet

PCBSky HDI PCB Structures

1. 1+N+1 - PCBs contain 1 "build-up" of high-density interconnection layers.

2. i+N+i (i≥2) - PCBs contain 2 or more "build-up" of high density interconnection layers. Microvias on different layers can be staggered or stacked.

3. Copper filled stacked microvia structures are commonly seen in challenging designs.

4. Any Layer HDI - All the layers of a PCB are high density interconnection layers which allows the conductors on any layer of the PCB to be interconnected freely with copper filled stacked microvia structures ("any layer via"). This provides a reliable interconnect solution for highly complex large pin-count devices, such as CPU and GPU chips utilized on handheld and mobile devices.

PCBSky HDI PCB Capabilities: Microvias PCB

A microvia maintains a laser drilled diameter of typically 0.006" (150µm), 0.005" (125µm), or 0.004" (100µm), which are optically aligned and require a pad diameter typically 0.012" (300µm), 0.010" (250µm), or 0.008" (200µm), allowing additional routing density. Microvias can be via-in-pad, offset, staggered or stacked, non-conductive filled and copper plated over the top or solid copper filled or plated. Microvias add value when routing out of fine pitch BGAs such as 0.8 mm pitch devices and below.

Additionally, microvias add value when routing out of a 0.5 mm pitch device where staggered microvias can be used, however, routing micro-BGAs such as 0.4 mm, 0.3 mm, or 0.25 mm pitch device, requires the use of Stacked MicroVias using an inverted pyramid routing technique.

Any PCB Layer HDI

1. Multilayer copper filled stacked micro via structure

2. 3/3 mil line/space

4/8 mil laser via capture pad size

Material Options

High temperature FR4

Halogen - Free

PCBSky is a professional PCB/FPC/SMT Manufacturer in China, specializing in Quick Turn PCB & Prototypes. If you are looking for custom circuit board china, Welcome to order hdi pcb fabrication at a very competitive HDI PCB price.

This comment has been removed by a blog administrator.

ReplyDelete